TRIM SAW MACHINE

FEATURES :

Trim Saw Machine is suitable for slicing of raw gemstone into small /desired pcs.

The machine also performs trimming operation to remove surface impurity of the gemstone helping assorter to judge the stone accurately.

Coolant stored in the main body of the machine is sprayed on to the gemstone by rotary force of sawing blade to maintain the desired temperature.

The machine is suitable for slicing of all kind of gemstones from 3 to 25 mm pc.sizes

Suitably mounted on Wooden Table with Lighting arrangement

Splash Guard to protect operator

DUAL GRINDER FOR PRESHAPING

FEATURES :

The Pre shaping Machine is a versatile & useful machine suitable for pre shaping of faceted as well as Cabochon gemstones.

The Machine is robust & durable to perform pre shaping of small to far size pcs of all kind of gemstones from 2 mm to 100 mm

Versatile for Amethyst, Citrine, Emerald, Ruby, Peridot, Aquamarine, Sapphire and other Gemstones .

Four artisans can work on this machine so high productivity.

The machine is suitable for pre shaping of Round, Oval, Pear, marquise, Octagon, Square, Heart, Trillion and other fancy shapes in various sizes.

Supplied with Cooling & Lighting arrangement

Mounted on Wooden Top

Supplied with Tools & Accessories

UNIVERSAL CALIBRATION MACHINE

FEATURES :

Semi Automatic Universal calibration machine is a versatile precision machine suitable for calibration of faceted as well as Cabochon gemstones.

Can calibrate 3 to 30 mm sizes Gemstones with High +_ 0.05 mm accuracy

The machine performs Girdle and pavilion cutting in one setting so ensure better accuracy and high productivity.

The Automatic collet holding device and micro adjusting system of the Machine ensure the precision calibration of the pc. with close tolerance as per ICA specifications. Supplied with Coolant & Lighting arrangement

The machine is suitable for calibration of Round, Oval, Pear, marquise, Octagon, Square, Heart, Trillion and other fancy shapes in various sizes.

CABOCHON POLISHING MACHINE

FEATURES :

The Cabochon Machine is a versatile & useful machine for making Cabochon of small to far sizes in Round, Oval, Pear, Heart, Square, Octagon & other Fancy shapes of different gemstones.

Four artisans can work on this machine- 2 artisans can work on Finishing operation and other 2 artisans can work on Polishing operation so highly productive Machine

Suitable for Garnet, Citrine, Amethyst, Emerald, Tourmaline, Aquamarine and other Gems

Supplied with Coolant having filtering partition & Lighting arrangement

Supplied with Table, Facilities for Doping of Gems, Tools, Consumable & accessories

FACETING & POLISHING MACHINE

TECHNICAL SPECIFICATIONS:

Dual Arbour & Precision and Versatile F & P Machine for Cutting & Polishing of Gemstone.

Shape & Sizes : Round, Oval, pear, Square, Octagon, Marquoise,

Heart, Trillion, Cushion and other Shapes

Sizes : from 2 mm to 25 mm

Cuts : Brilliant, Step, Rose, Thai, Kamal and other Fancy

Cuts

POWER : 180 W X 230 V: Single Phase: 50 HZ

FACETING LAP : 600 / 1200 Grit Diamond Lap for extra fine

Cutting and pre polishing

POLISHING LAP : Cu / Tin alloy with Diamond charged

COLLET BORE : 6 mm

SPEED : 500 – 2000 rpm

DIMENSION / Wt. : 800 x 1000 mm / 45 Kg

PRODUCTIVITY : 30-50 Pcs. / Day of 4×6 to 6×8 mm sizes.

Facetors : 4 Nos Universal Precision Facetors mutually

synchronized

Supplied with Table for Machine and space for dopping of Gems with Tools,

Consumables & complete accessories

VIBRATORY POLISHER

FEATURES :

The vibrator is mounted on a mild steel sheet rounded into a pipe shape. It comes fitted with a motor of 1/2 h.p. 2800 r.p.m. which is fixed with weights for effecting vibrations. The main container is made of Teflon for wear resistance & scratch free performance. * The vibrator is designed for up to 4Kg. Load at one time.

Suitable for Amethyst, Citrine, Rhodolite, Garnet, Peridot, Emerald, Onyx, Quartz, Labdorite, chalcedony and other Gems in Tumble, Bead, Drops, Cabochoun & other Forms.

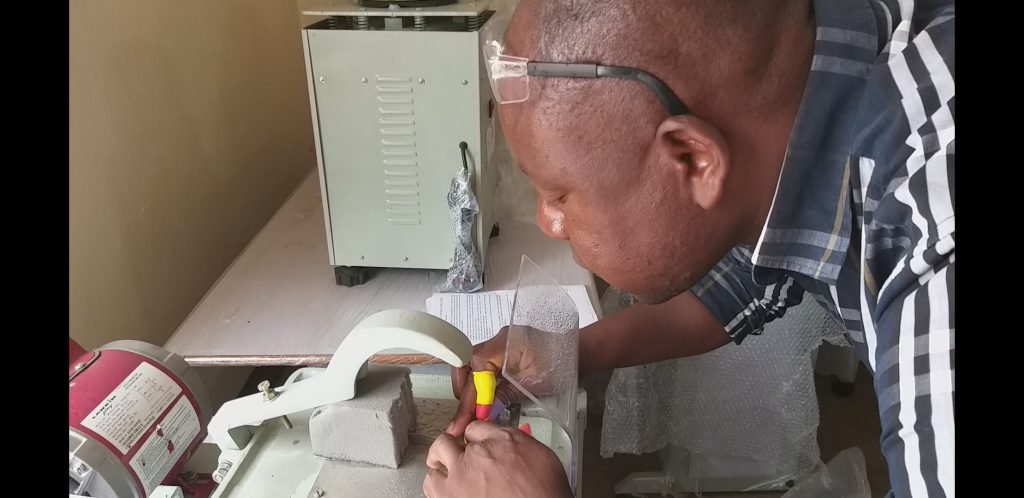

ULTRA SONIC DRILLING MACHINE

Ultrasonic drilling machines a method of brittle destruction by collision of abrasives which are forced against a work by an ultrasonically vibrated tool assisted by an appropriate clamping force. The tool vibration can be of amplitude approx. 40-80 microns with frequencies of 25 kHz, sufficient to perform effective machining. Abrasives may be carborundum, boron carbide or diamond powder depending upon each work. Rougher grits provide quicker chipping but it rougher finish, Abrasives are usually used in slurry (mixed with water).

SPECIFIC FEATURES: 1. Suitable for precise machining of any hard and brittle material; specifically drilling, Semi precious & precious stones from RH 5 to Rh 9 stones.

- Drill Size from 0.50 to 2.0 mm dia. 3. Mounted with Table, supplied with Lighting arrangement,

- Simple in operation even a beginner can operate the machine with ease. 5. Very low operative cost. Less than 4% weight loss in drilling on an average.

- Ultrasonic Unit : 25 KHZ, 50 W, Auto Tuning

- Transducers : Electrostrictive PZT

- Power : AC 220 V V 50 HZ, APPROX 100VA